Efficiency in a Pharmaceutical Laboratory Bench is crucial. According to Dr. Emily Chen, an expert in laboratory design, "Every inch counts in a lab." Her insight emphasizes the importance of optimizing space for maximum productivity.

The arrangement of equipment and materials can significantly influence daily operations. Lab technicians often face cluttered benches that hinder their performance. Tools and samples should be organized logically, reducing the time spent searching for essential items. This organization not only saves time but also minimizes errors.

Moreover, consider ergonomics in the design of the Pharmaceutical Laboratory Bench. A workspace that is comfortable can improve focus and decrease fatigue. However, many labs overlook this aspect, leading to inefficiencies. Reflection on these points can foster a more effective laboratory environment, ultimately benefiting research outcomes.

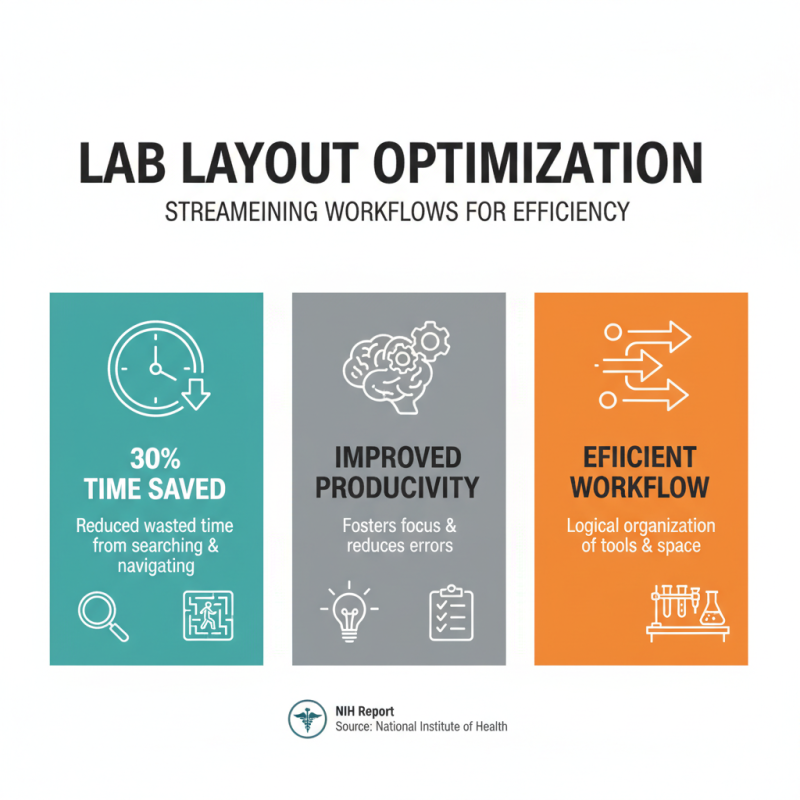

Assessing the current laboratory layout is crucial for streamlining operations. A report by the National Institute of Health reveals that up to 30% of a lab's time may be wasted on inefficient workflows. Scientists often spend excessive hours searching for tools or navigating cluttered spaces. Simplifying the layout can foster a flow that reduces unnecessary movement.

Analyzing workflow patterns reveals bottlenecks. For example, equipment positioned too far from workstations can slow down experiments. By examining task frequency and proximity, adjustments can be made. A study indicated that rearranging equipment can lead to a noticeable 20% increase in productivity. However, many labs still struggle with optimal arrangements.

Often, labs overlook the importance of collaborative spaces. These areas should encourage discussion and idea sharing. Yet, many fail to implement this, leading to isolation. Integrating informal meeting zones might enhance team dynamics. Balancing privacy with collaboration is a challenge worth exploring, as it can significantly impact lab efficiency.

Optimizing a pharmaceutical laboratory bench is crucial for efficiency. According to a study from the Pharmaceutical Research and Manufacturers of America, labs can improve productivity by up to 30% through proper layout and organization. Identifying key areas for improvement is essential. Start by assessing workflow patterns. Understand how materials and information flow within the lab.

Tip: Create a flowchart to visualize the current workflow. This will help pinpoint bottlenecks. Many labs neglect the importance of ergonomics. Work surfaces should be at comfortable heights. Cluttered benches can hinder productivity. Empty spaces for tools and materials promote better focus.

Additionally, consider technology integration. Implementing digital lab notebooks can reduce time spent on documentation. A report from LabManager indicates that digital solutions can cut data entry time in half. However, some may resist this change due to attachment to traditional methods. Engaging staff in these discussions fosters a culture of improvement. Regular feedback sessions can highlight areas needing adjustments.

| Key Area | Current State | Optimization Strategies | Expected Outcome |

|---|---|---|---|

| Workflow Layout | Inefficient, many back-and-forth movements | Redesign layout based on workflow analysis | Reduce time and increase productivity |

| Equipment Access | Equipment spread out, hard to reach | Consolidate equipment in a central location | Faster access to tools, saving time |

| Sample Management | Manual tracking, prone to errors | Implement a digital tracking system | Increased accuracy and reduced loss |

| Safety Protocols | Inconsistent adherence | Regular training and reminders | Improved safety and compliance |

| Inventory Management | Overstock and stockouts | Adopt a just-in-time inventory system | Balanced stock, reduced waste |

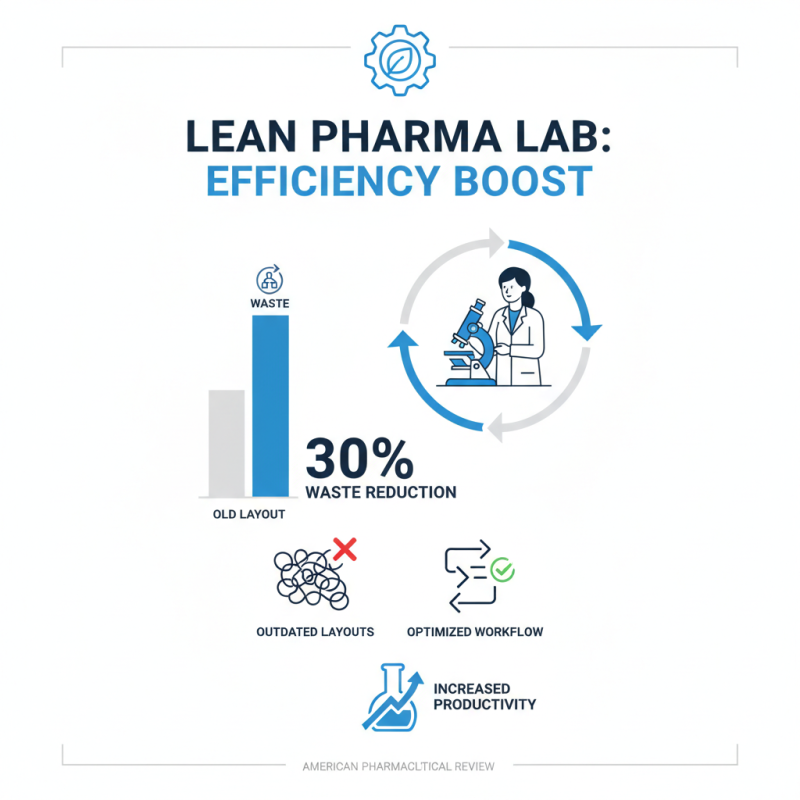

Implementing lean principles in pharmaceutical laboratories can significantly enhance efficiency. A study by the American Pharmaceutical Review indicates that labs can reduce waste by up to 30% through effective space management and resource allocation. Many labs still use outdated layouts, leading to wasted time and resources. By rethinking the arrangement of workstations and equipment, labs can streamline workflows and improve productivity.

Creating a more efficient laboratory environment involves careful planning. For instance, placing frequently used samples and tools within easy reach minimizes movement. In one study, labs reported improving their output by 25% simply by reorganizing workspaces based on lean principles. Some scientists hesitate to adjust their environments, though. They worry about disrupting established routines. This hesitation can lead to missed opportunities for improvement.

Data indicates that poorly optimized labs can consume up to 40% more resources than necessary. This inefficiency affects both productivity and costs. Regular evaluations of space and resource usage can reveal areas needing attention. Small, continuous improvements can lead to significant gains. Being open to feedback and willing to experiment is crucial. Adaptation is a part of the process in pursuit of efficiency.

In a pharmaceutical laboratory, optimizing the bench for efficiency is crucial. Technology plays a significant role in this process.

Automated systems can streamline repetitive tasks. This minimizes human error and reduces time spent on mundane activities.

Lab personnel often face workloads that lead to fatigue. Automation can alleviate some of this pressure, allowing for a focus on complex tasks.

Incorporating lab management software can enhance productivity further. This software can track experiments and manage inventory. Yet, issues like software glitches can arise, causing delays.

Regular updates and staff training are essential to mitigate these setbacks. Real-time data access is vital, but it can sometimes lead to information overload.

Striking a balance is key.

Smart equipment, such as robotic arms, can assist in sampling and analysis. However, malfunctioning machines can disrupt workflow.

Regular maintenance schedules are necessary but can be overlooked. Developing a culture where staff report issues promptly can prevent larger problems.

Embracing technology is essential, but constant evaluation of these systems is equally important.

Engaging staff in a pharmaceutical laboratory is crucial for optimizing efficiency. Training should not be a one-time event. Regular workshops help keep the team updated on best practices and new technologies. Activities like role-playing and group discussions can make learning interactive. This creates a more dynamic environment.

However, the training process isn't always perfect. Sometimes, staff may feel overwhelmed by too much information. Additionally, not all employees engage equally during sessions. It can lead to inconsistencies in knowledge across the team. Some might need additional follow-up training to reinforce concepts.

Encouraging feedback is essential. Employees should feel comfortable sharing their thoughts on training methods. Some may find certain topics irrelevant or difficult to grasp. Listening to them allows for necessary adjustments. A culture of continuous improvement thrives on clear communication and support. Creating a safe space for discussions ensures everyone feels valued. This, in turn, leads to a more efficient laboratory environment.